A Review Of precision machining

Once you style an element, it’s as significant to think about wall thickness as the beauty of the look.

We are aware that shoppers select BPM simply because we supply Excellent outcomes. That has a focus on steady enhancement, we have been self-confident of preserving to our large expectations. It also helps make us mindful of adjusting marketplace wants as we attempt to evolve and increase.

Ultrasonic machining centres are employed for brittle resources for instance ceramics, vibrating the floor and taking away smaller particals. Ceramic elements are often Employed in inspection devices for measuring gap tolerances. 4 people today uncovered this helpful

precision machining No Further a Mystery

The moment that Slice is finished, I'd like to eliminate every one of the tooling marks developed by the tip mill. If I try employing a belt sander or maybe manually sanding, I get a fantastic finish, but end up inevitably rounding my great flat surface.

We nevertheless retain our primary buyers, which speaks volumes about our perseverance to high quality and customer support. You may learn more about our abilities and solutions if you take a look at us online today!

As material passes from the chopping region of the milling equipment, the blades from the cutter acquire swarfs of material at normal intervals. Surfaces Lower with the facet of your cutter (as in peripheral milling) as a result generally incorporate standard ridges.

CNC routers, However, are perfect for cutting tender sheet components including Wooden and aluminum and tend to be more cost-efficient than using a CNC mill for a similar job. For tougher sheet elements like metal, a waterjet, laser, or plasma cutter is needed.

Finishing cuts are applied to accomplish the aspect and realize the final dimension, tolerances, and area end. In generation machining Work, one or more roughing cuts are generally carried out on the perform, followed by a few finishing cuts. Roughing operations are accomplished at substantial feeds and depths – feeds of 0.

New Step by Step Map For precision machining

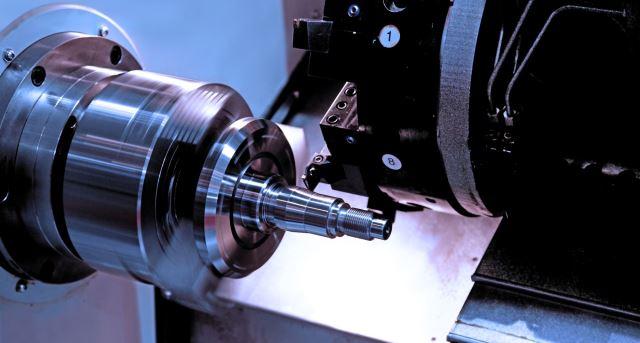

Precision machining utilizes specialised software program in conjunction with CAD/CAM computer software systems to instruct the tooling to execute the exact actions needed to build the component.

A slicing Instrument has a number of sharp chopping edges and is made of a fabric that may be tougher than the do the job product. The cutting edge serves to different chip through the mother or father work materials. Connected to the innovative are The 2 surfaces from the Software:

Machining functions usually divide into two categories, distinguished by function and slicing ailments:

, "Do motorists not use their blinkers any longer or are they low on blinker fluid?," 24 June 2017 What took place to rebuilding calipers and machining rotors? — Bob Weber, chicagotribune.com

Details, Fiction and precision machining

To be a business venture, machining is mostly performed in the device store, which is made up of one or more usinagem workrooms containing significant machine instruments.